![]() Your current location:Products

Your current location:Products

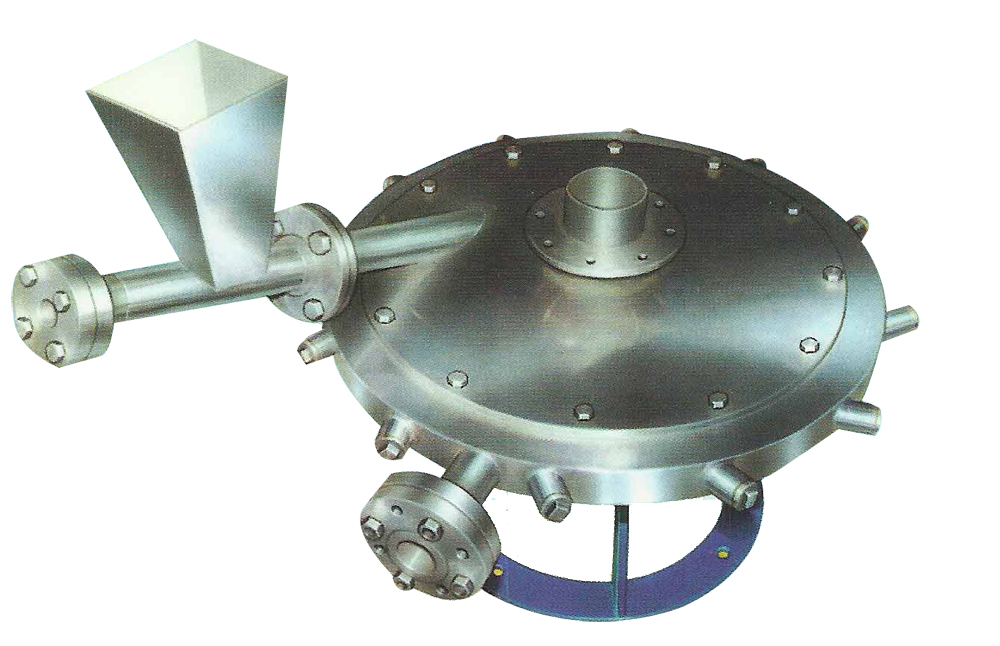

Features:

Stainless steel, corrosion resisting;

High purity alumina or special wear-resistant material as lining;

Appropriate for heat sensitive material;

Different micron granule can be gained by the adjusting of pressure and air quantity;

Appropriate range:

chemical, mineral products, construction material, electron, pharmaceutical, coating, dyes, light industry, food, metallurgy, feed and titanium dioxide

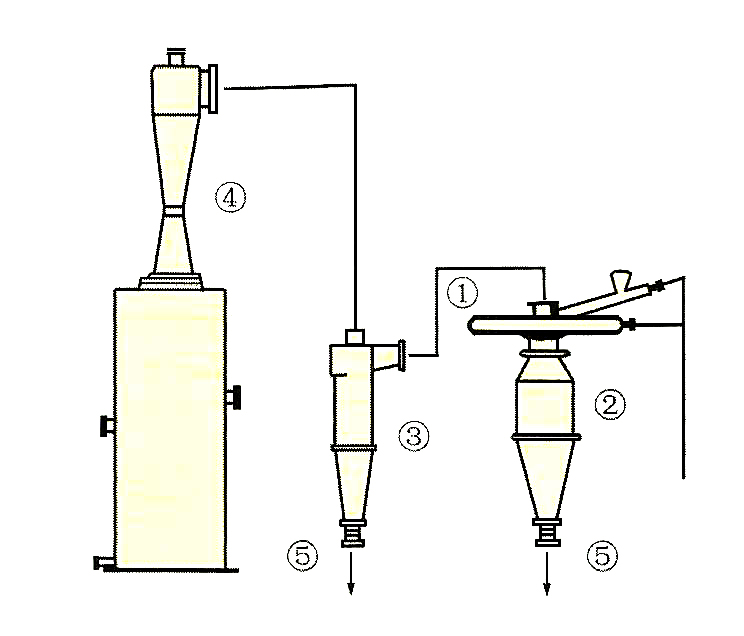

A flow diagram

.jpg)

A

| ADS600 | ADS1100 | |

| feeding pressure | 0.6~1.0Mpa | 0.6~1.0Mpa |

| grinding pressure | 0.6~1.0Mpa | 0.8~1.0Mpa |

| gas consumption | 18-28m3/min | 88.1-121m3/min |

| handling capacity | 200-600kg/h | 1000-3000kg/h |

| size(Φ×H) | 1000×1900(mm) | 1600×1156(mm) |

| weight | 330kg | 1163kg |

| air compressor power | 132-250kw | 600-750kw |

①air compressor

②air storage tank

③freezing compressed air drier

④QS jet mill

⑤cyclone separator

⑥star shape rotary valve

⑦impulse type drip catcher

⑧induced draft fan

B flow diagram

B

| ADS600 | ADS1100 | |

| superheated steam consumption | -1200KG/J | 3300-3500KG/H |

| superheated steam temperature | 315~380℃ | 315~380℃ |

| superheated steam pressure | 0.8-1.6Mpa | 0.8-1.6Mpa |

| feeding partical size | <100um | <100um |

| feeding temperature | environmental temperature | environmental temperature |

| production capacity | 300-600kg/h | 100-1500kg/h |

①QS600 jet mill

②1st grade drip catcher

③cyclone separator

④venturi scrubber

⑤star shape rotary valve